THE AGROMAT UNIT

This automatic grass production unit guarantees a steady supply of ONE TON PER DAY of fresh, highly nutritive green fodder, independent of weather conditions. The containerized unit occupies 36 m², and replaces the capacity of 10 hectares of grazing land. The AGROMAT unit was the first scientific and technological equipment developed and sold by AGROTECH BELGIUM, that became hereby world-famous. AGROMAT was a giant leap in the field of applied agricultural technology. However, today, the AGROMAT unit is not advised and produced anymore, as a result of the worldwide dramatic price rise of steel in early 2004 that made this unit too expensive, taking into account its quite limited output capacity. Moreover, the insurance premium for the shipment of containerized equipments, as well as the shipment cost for non-standard containers have also dramatically risen in a few years. Consequently, AGROTECH BELGIUM developed a technical solution, based on the same GERM technology that is financially much more interesting, and more adapted to professional end-users (see hereafter).

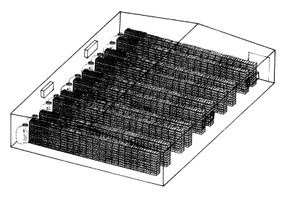

THE FRESH FODDER FACTORY

Such a fresh cereal fodder production plant is also based on the GERM technology, and is characterized by an output capacity that may amount MANY TENS OR HUNDREDS OF TONS PER DAY to answer the needs of an industrial farm, a community of farmers or a whole agricultural region. It consists in a building that is adequately arranged, insulated and conditioned, in which the technological equipments have been installed. This solution allows a cut down of the investment per ton by 20 to 30%. Such FRESH FODDER FACTORIES are professional and industrial projects managed by a staff of specialists (zootechnician and technician) in order to optimize zootechnical performances, and to guarantee an efficient and professional running of the operation.

The field of application is diversified:

- INTEGRATED PART OF AN INDUSTRIAL FARM (milk or meat production, breeding, …)

- ON-SITE FEEDING STATION MANAGED BY A PUBLIC SERVICE (City Council, public cooperative, …) OR BY PRIVATE INVESTORS WHO SELL RETAIL THE GREEN FODDER TO SMALL FARMERS

- WAITING ZONE OF A SLAUGHTER-HOUSE (fast weight increase before slaughter)

- etc.

- INTEGRATED PART OF AN INDUSTRIAL FARM (milk or meat production, breeding, …)

- ON-SITE FEEDING STATION MANAGED BY A PUBLIC SERVICE (City Council, public cooperative, …) OR BY PRIVATE INVESTORS WHO SELL RETAIL THE GREEN FODDER TO SMALL FARMERS

- WAITING ZONE OF A SLAUGHTER-HOUSE (fast weight increase before slaughter)

- etc.

Inside of FFFThe Fresh Fodder Factory is a very profitable investment.

Numerous studies realized worldwide by AGROTECH BELGIUM have systematically showed outstanding profitability ratios.

Consequently, there is an obvious interest from public or private investment companies that are interested in a Fresh Fodder Factory or a national or regional network of Fresh Fodder Factories to sell the fodder retail to small farmers and to give a boost to the stockbreeding sector in their respective countries.